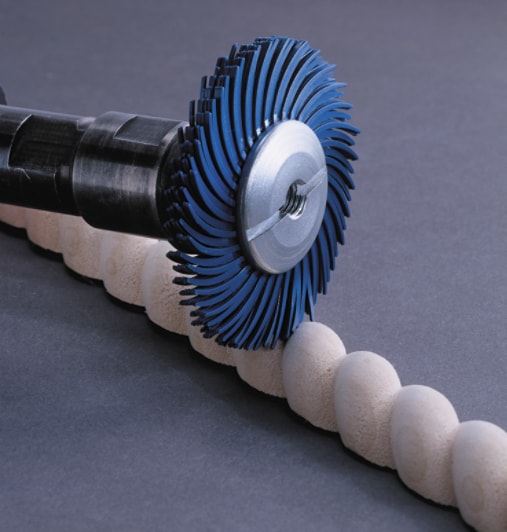

Scotch-Brite™ Radial Bristle Brush

- | Select product options for IDs.

Details

Highlights

- RECOMMENDED APPLICATIONS: Effectively deburr, clean and finish

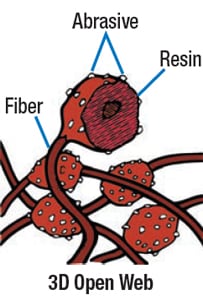

- PROPRIETARY 3M CERAMIC ABRASIVE GRAIN: Delivers consistent finish quality throughout the entire lifespan of the disc

- FLEXIBLE AND CONFORMABLE: Flexible bristles require less pressure than wire brushes and conform to contours, even on complex parts in robotic processing

- MOLDED, ABRASIVE-FILLED BRISTLES: Remove coatings with greater efficiency and less pressure compared to wire brushes

- IDEAL BRISTLE SPACING: Designed for high-loading substances, ensuring optimal performance

- WIRE FILAMENT-FREE: Enhances safety by eliminating wire filaments commonly found in wire brushes

- AVAILABLE IN A RANGE OF GRADES: 36, 50, 80, 120, 220, 400

Scotch-Brite™ Radial Bristle Brush, using a proprietary ceramic abrasive grain blended with aluminum oxide and molded, flexible bristles, provides more surface contact than wire brushes and maintains abrasive property throughout the life of the brush. This brush removes paint, stains, adhesives, weld burns, rust, heavy oxides, and surface contaminants.

Typical Properties

| Applications | Finishing, Deburring, Cleaning |

| Attachment Type | Centre Hole |

| Brands | Scotch-Brite |

| Bristle Type | Type C (Curved), Type A (Angled) |

| Centre Hole Diameter (Metric) | 25.4 mm |

| For Use With | Manual Backstand |

| Grit | 36, 50, 80, 120 |

| Industries | Aerospace, Metalworking, General Industrial, Transportation & Heavy Equipment, Marine |

| Max Speed | 6000 rpm |

| Micron Grade | 0.0 |

| Mineral Type | Ceramic |

| Product Colour | White, Dark Brown, Yellow, Green |

| Product Form | Brush |

| Stack Height (Metric) | 11.1125 mm, 12.7 mm |

| Sub Applications | Mill Scale Removal, Weld Cleaning, Descaling, Contour Finishing, Surface Preparation |

| Sub Industries | Metal Fabrication |

| Overall Diameter (Metric) | 152.4 mm |

| Overall Width (Metric) | 11.1125 mm, 12.7 mm |

Resources

Brochures

(PDF, 10MB)

3M Abrasive Catalogue AU 2021

3M Abrasive Catalogue AU 2021 Scotch-Brite™ Radial Bristle Brush

Scotch-Brite™ Radial Bristle Brush Scotch-Brite™ Radial Bristle Brush Replacement Disc

Scotch-Brite™ Radial Bristle Brush Replacement Disc Scotch-Brite™ Radial Bristle Disc

Scotch-Brite™ Radial Bristle Disc Scotch-Brite™ Bristle Disc

Scotch-Brite™ Bristle Disc