3M™ Cubitron™ II Depressed Center Grinding Wheel

- 3M ID B40065261

Details

Highlights

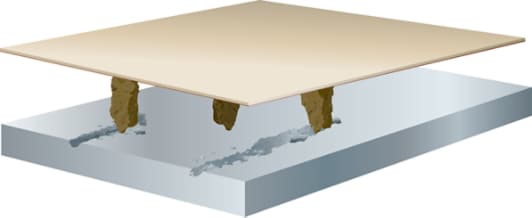

- 3M™ Cubitron™ II grain cuts extra fast and cool and is ideal for weld removal in industrial operations

- 3M-engineered triangular shaped grain wears evenly, runs cool, and optimizes mineral breakdown, providing extra long life for wheel and tool

- Specially formulated for use on almost all materials including stainless steel, mild steel, and aerospace alloys

- Quick change attachment enables easy change-outs by hand without tools

- Wheel must have a maximum operating speed greater than or equal to the maximum speed of the power tool used and must be used with a properly sized wheel guard

3M™ Cubitron™ II Depressed Center Grinding Wheel is constructed of 3M precision-shaped ceramic grain to bring you an exceptionally fast-cutting and long-lasting rigid bonded wheel for heavy weld removal and other heavy-duty grinding applications. Our grinding wheel works well on almost all materials and is specially formulated for use on stainless steel, mild steel, and aerospace alloys.

Typical Properties

| Brands | Cubitron™ |

| Equipment - Machines | Right Angle Grinders |

| Grit | 36+ |

| Mineral Type | Precision Shaped Ceramic |

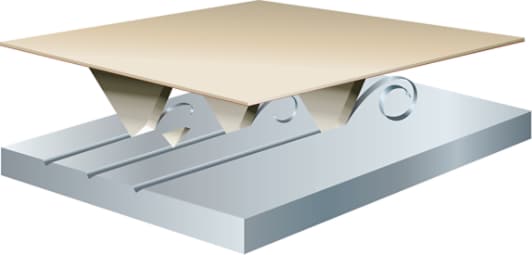

| Product Form | Grinding Wheel |

| Wheel Type | Type 27 |